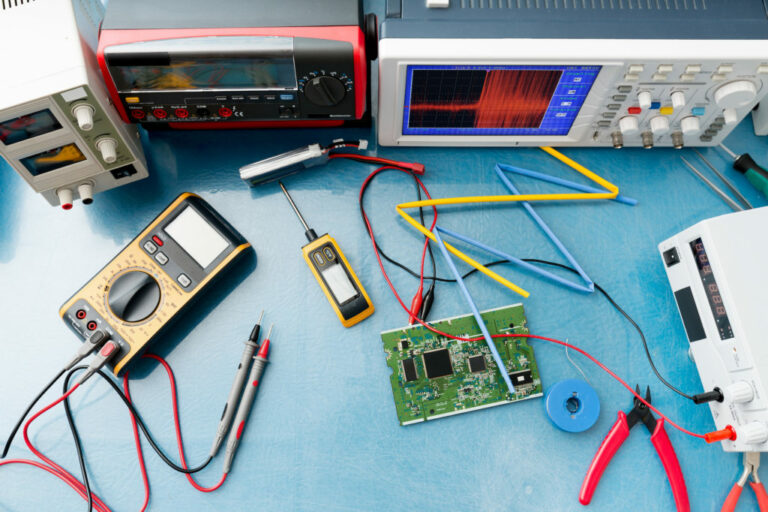

Prism Calibration offers power calibration services for all types of equipment. Our highly trained technicians use state-of-the-art equipment to ensure accurate measurements and reliable results.

Calibration is necessary to ensure the accuracy and reliability of power measurements. Over time, factors such as component aging, environmental conditions, and wear and tear can affect the performance of power measurement devices, leading to potential inaccuracies.

Calibration of power measurement equipment involves comparing the readings of the instrument against a known reference standard or a traceable calibration device. This process helps identify any deviations or errors in the measurements and allows for adjustments to be made to improve accuracy.

Accurate power measurement is crucial in various industries and applications, including electrical testing, manufacturing, energy management, research and development, and more. Calibration ensures that power meters, power analyzers, and other power measurement devices provide precise and reliable measurements.

Ensure accuracy: Calibration verifies the accuracy of power measurement devices, allowing you to trust the readings and make informed decisions based on accurate data.

Maintain compliance: Many industries have regulatory standards and requirements for power measurement accuracy. Calibration ensures that your equipment meets these standards and helps you maintain compliance.

Optimize performance: Calibration helps identify any drift or inaccuracies in power measurement devices, allowing for adjustments or repairs to optimize their performance and minimize measurement errors.

Quality control: Accurate power measurement is essential for quality control processes. Calibration ensures that your power measurement equipment provides reliable data for quality assurance and process optimization.

It’s important to follow a regular calibration schedule recommended by the manufacturer or calibration standards to maintain the accuracy and reliability of power measurement equipment. Calibration should be performed by a qualified calibration service provider or laboratory to ensure traceability and adherence to industry standards.

Calibrating a power meter involves several steps to ensure accurate and reliable energy measurement. Here is a general guide on how to calibrate an energy meter:

Gather Calibration Equipment: Collect the necessary equipment for energy meter calibration, including a calibrated reference standard or a traceable calibration device, appropriate test leads, and any required auxiliary equipment.

Preparation: Ensure that the energy meter is properly installed and connected to the electrical circuit. Make sure all connections are secure and there are no loose or damaged wires.

Verify Meter Settings: Check the energy meter’s settings, such as voltage, current range, and power factor, to ensure they are correctly configured for the calibration procedure.

Perform Zero Adjustment: Set the energy meter to its zero point or adjust it to a known zero value. This compensates for any offset or drift in the meter’s readings.

Establish Calibration Standards: Connect the calibrated reference standard or traceable calibration device to the energy meter. Ensure that the standards are stable, calibrated, and suitable for the required measurement range.

Conduct Calibration: Apply known voltage and current values to the energy meter, representing typical operating conditions. Measure and record the energy meter’s readings.

Compare Readings: Compare the energy meter’s readings with the readings from the calibrated reference standard or traceable calibration device. Note any differences or deviations.

Adjust and Verify: If the energy meter’s readings deviate from the reference standard, make appropriate adjustments to correct the measurements. Follow the manufacturer’s instructions or consult calibration guidelines for specific adjustment procedures.

Repeat Calibration: Perform multiple calibration measurements across different ranges and operating conditions to ensure accuracy throughout the energy meter’s specified range.

Record Calibration Data: Document all calibration data, including the energy meter’s readings, reference standard values, adjustment details, and any other relevant information. This documentation serves as a calibration record and can be used for future reference.

Calibration Certificate: Upon completion of calibration, generate a calibration certificate that includes all relevant information, such as the date of calibration, equipment used, calibration results, and the technician’s signature. This certificate provides proof of calibration and compliance with industry standards.

It is recommended to follow the energy meter manufacturer’s guidelines and consult with a qualified calibration service provider or laboratory for specific calibration procedures and best practices.

Power calibration services offer several benefits to industries and businesses that rely on accurate power measurement. Here are some key benefits of power calibration services:

Accuracy and Reliability: Power calibration ensures that your power measurement instruments provide accurate and reliable readings. Calibration compares the measurements of your instruments against traceable standards, identifying any deviations or errors and allowing adjustments to be made. Accurate power measurements enable better decision-making, improved quality control, and increased confidence in your power data.

Compliance with Standards: Many industries have regulatory standards and requirements for power measurement accuracy. Power calibration services ensure that your instruments meet these standards, helping you maintain compliance with industry regulations. Calibration certificates provide documented evidence of compliance, which is often necessary for audits, certifications, and regulatory inspections.

Optimized Performance: Regular calibration helps identify any drift, non-linearity, or inaccuracies in power measurement instruments. By detecting and rectifying these issues, calibration helps optimize the performance of your instruments, ensuring they deliver accurate measurements. This leads to improved operational efficiency, reduced errors, and enhanced productivity.

Cost Savings: Calibration helps prevent costly errors and inefficiencies that may arise from inaccurate power measurements. Accurate measurements can lead to more efficient energy consumption, reduced waste, and better resource allocation. By maintaining accurate power measurements, you can avoid unnecessary expenses associated with rework, product failures, or non-compliance penalties.

Increased Equipment Lifespan: Power calibration often includes preventive maintenance checks and adjustments. Regular calibration and maintenance can extend the lifespan of your power measurement instruments by identifying and addressing potential issues early on. This reduces the risk of instrument failures and the need for premature replacements, ultimately saving you costs in the long run.

Quality Assurance: Accurate power measurements are crucial for quality control and product testing processes. Calibration ensures that your instruments provide reliable data for quality assurance, helping you maintain consistent product quality and reliability. It also enhances customer satisfaction by ensuring that your products meet or exceed performance specifications.

Traceability and Documentation: Power calibration services provide traceability by comparing measurements against recognized standards. Calibration certificates serve as documented evidence of calibration and compliance, offering traceability to national or international standards. These certificates can be easily accessed and stored for record-keeping, audits, and regulatory purposes.

Accurate power measurement is crucial in industries like telecommunications, electronics and renewable energy. Prism Calibration offers fast turnaround times and flexible scheduling to fit your requirements.

Our calibration lab is accredited to ISO 17025 standards (NABL), ensuring the highest level of precision and accuracy. Our traceable calibration certificates provide you with confidence in your power measurement results.

Get in touch to schedule power calibration service. Our team is available to guarantee equipment accuracy.