Dimensional calibration is the process of verifying and adjusting the accuracy of measurement tools used to determine the physical dimensions of objects. These tools, such as micrometers, vernier calipers, and dial indicators, are critical in industries where precision is paramount. Over time, these instruments can drift from their original settings, leading to inaccurate measurements and potential quality issues.

At Prism Calibration, we offer laboratory calibration services and on-site calibration services tailored to your specific needs. Our adherence to ISO 17025 calibration standards and NIST traceability guarantees the highest levels of calibration accuracy and regulatory compliance.

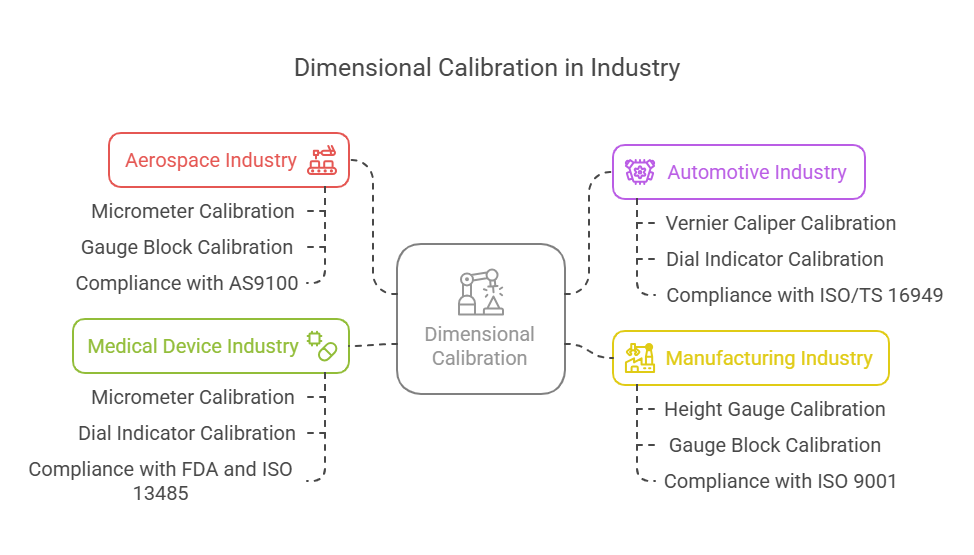

Micrometer calibration: Ensures precise measurements of aircraft components.

Gauge block calibration: Critical for maintaining the accuracy of tooling and fixtures.

Compliance: Meets AS9100 standards for aerospace quality management.

Vernier caliper calibration: Ensures accurate measurements of engine parts and assemblies.

Dial indicator calibration: Critical for alignment and inspection processes.

Benefits: Improves product quality, reduces waste, and ensures compliance with ISO/TS 16949 standards.

Height gauge calibration: Ensures accurate measurements in machining and fabrication processes.

Gauge block calibration: Critical for maintaining the accuracy of reference standards.

Benefits: Enhances production efficiency, reduces rework, and ensures compliance with ISO 9001 standards.

Micrometer calibration: Ensures precise measurements of medical components.

Dial indicator calibration: Critical for quality control in manufacturing.

Compliance: Meets FDA regulations and ISO 13485 standards.

– Bore Micrometers

– Internal Micrometers

– External Micrometers

– Depth Micrometers

– Blade Micrometers

– Bevel Protractor

– Vernier Bevel Protractor

– Indicator Bevel Protractor

– Optical Bevel Protractor

– Metric Bevel Protractor

– Dumpy Level

– Automatic Level

– Optical Level

– Laser Level

– Bubble Level

– Laser Spirit Level

– Spirit Level

– Digital Level

– Rotation Laser Level

– Rotating Laser Level

– Rotary Laser Level

– Set Square

– Try Square

– Engineer Square

– Combination Square

– Steel Rule

– Straight Edge

– Stainless Steel Rule

– Tape Measure

– Stanley Tape Measure

– Laser Distance Meter

– Fibre Tape Measure

– Laser Measure

– Measuring Tape

– Plunger Dial Indicator

– Dial Test Indicator

– Digital Dial Indicator

– Mechanical Dial Indicator

– Dial Gauge

– Metric Feeler Gauge

– Imperial Feeler Gauge

– Go NoGo Feeler Gauge

– Feeler Gauges

– Angle Gauge

– Radius Gauge

– Imperial Feeler Gauge

– Straight Leaf Feeler Gauge

– Offset Blade

– Valve Feeler Gauge

– Blade Feeler Gauge

– Thread Gauge

– Feeler Gauge Set

– Thickness Meter

– Handheld Thickness Gauge

– Ultrasonic Thickness Gauge

– Coating Thickness Gauge

– Digital Thickness Gauge

– Material Thickness Gauge

– Industrial Thickness Gauge

– Film Thickness Gauge

– Metal Thickness Gauge

– Wall Thickness Gauge

– Electronic Thickness Gauge

– Dial Thickness Gauge

– Calipers

– Digital Caliper

– Single Slip

– Slip Block Sets

– Gapping Rods

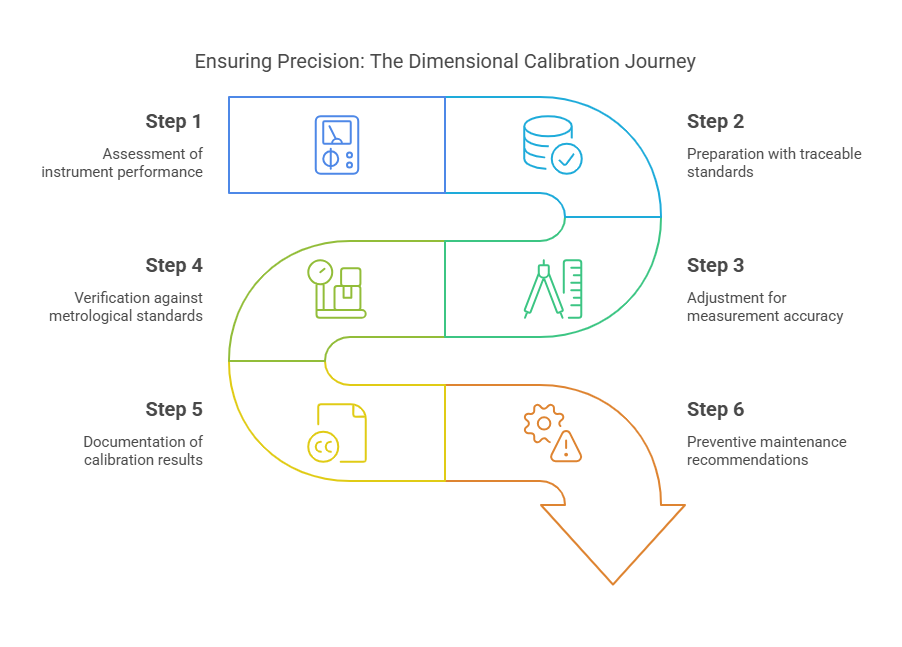

At Prism Calibration, we follow a meticulous step-by-step calibration process to ensure your dimensional measurement tools meet the highest standards. Here’s how we do it:

– Evaluate the instrument’s performance and identify calibration needs.

– Determine the appropriate calibration intervals based on usage and industry requirements.

– Use traceable standards and reference instruments for comparison.

– Ensure the calibration environment is controlled to avoid external factors affecting the results.

– Fine-tune the instrument to correct any deviations from the standard.

– Use advanced tools and techniques to achieve measurement accuracy.

– Test the instrument to ensure it meets metrological standards.

– Perform multiple tests to confirm consistency and reliability.

– Provide detailed calibration certificates that include performance data, adjustments made, and compliance information.

– Ensure the documentation is ready for audits and inspections.

– Recommend calibration intervals and maintenance tips to avoid future errors.

– Offer on-site calibration services for added convenience.

Regular calibration offers numerous advantages for industries relying on dimensional measurement tools, including:

– Ensures your instruments provide reliable and consistent data, reducing the risk of errors.

– Enhances decision-making and process control.

– Helps you meet industry standards and avoid penalties or legal issues.

– Provides documented proof of compliance through calibration certificates.

– Prevents costly operational errors and equipment failures by identifying issues early.

– Reduces the need for expensive repairs or replacements.

– Minimizes downtime by ensuring your instruments are always in optimal condition.

– Improves workflow efficiency by reducing the likelihood of errors.

– Ensures that instruments operate within safe parameters, reducing the risk of accidents.

– Critical for industries like aerospace and automotive.

– Regular calibration and preventive maintenance extend the lifespan of your instruments.

– Reduces the frequency of replacements and repairs.

At Prism Calibration, we leverage advanced technologies to enhance the accuracy and efficiency of our calibration services. These include:

– Automated calibration systems reduce human error and improve consistency.

– Enhances the speed and accuracy of the calibration process.

– Digital readouts and software-based calibration tools provide precise measurements.

– Ensures traceability and documentation for compliance.

– High-precision laser systems for calibrating instruments like height gauges and dial indicators.

– Ensures measurement accuracy at the micron level.

We adhere to the highest industry standards and certifications, including:

– Ensures the competence of testing and calibration laboratories.

– Guarantees measurement accuracy and traceability.

– Provides documented proof that calibration results are aligned with national standards.

– Ensures transparency and accountability in calibration processes.

– Meets requirements for certifications like ISO 9001, AS9100, and ISO/TS 16949.

At Prism Calibration, we stand out for our:

– Expertise: Years of experience in calibrating micrometers, vernier calipers, gauge blocks, dial indicators, and height gauges.

– Accreditation: ISO 17025-certified calibration services and NIST traceability.

– Comprehensive Services: From laboratory calibration services to on-site calibration services, we cover all your needs.

– Customer-Centric Approach: Tailored solutions to meet your specific requirements.

– Advanced Technologies: State-of-the-art tools and techniques for precise calibration.

– Detailed Documentation: Provides calibration certificates, reports, and records for compliance.

Dimensional calibration ensures your measurement instruments are accurate by comparing them to a standard reference.

Dimensional calibration frequency depends on usage, environment, and industry needs, but typically once a year is recommended.

Micrometers, protractors, levels, squares, vernier calipers, dial indicators, tape measures, and more.

We follow ISO, NIST, and other recognized industry standards, issuing traceable calibration certificates.

Calibration adjusts the instrument to a standard, while verification checks accuracy without adjustments.

Yes, we provide both onsite and in-lab calibration services for convenience and efficiency.

We serve industries such as automotive, aerospace, manufacturing, construction, and medical devices.

Inspection, adjustment, comparison to standards, and a detailed calibration certificate.

A calibration certificate detailing the results, traceability, and next calibration due date.

Contact us via our website or customer service to arrange flexible scheduling options.

Yes, we handle custom and specialized instruments with tailored calibration services.