The medical field demands an unparalleled level of precision and reliability. Every day, healthcare professionals rely on sophisticated medical equipment to diagnose, monitor, and treat patients. However, even the most advanced devices can lose accuracy over time due to regular use, environmental conditions, and aging components. This is where hospital equipments calibration plays a vital role. Proper calibration ensures that devices perform as intended, delivering accurate results critical to patient safety and healthcare quality.

This detailed guide explores how hospital equipments calibration impacts patient health and safety, why it’s indispensable, and how Prism Calibration expertise provides unparalleled support to the healthcare industry.

Understanding hospital equipments calibration

Hospital equipments calibration is the process of testing, verifying, and adjusting medical devices to meet predetermined performance standards. Calibration ensures that devices operate within defined tolerances, delivering consistent and precise results over time. This process involves using reference instruments traceable to international or national standards. Without regular calibration, devices risk inaccurate readings, leading to potential harm to patients and costly errors for hospitals.

The critical role of calibration in healthcare

- Enhancing diagnostic accuracy: Medical diagnostics form the foundation of effective treatment. Devices such as blood glucose monitors, X-rays, CT scanners, and ECG machines play a pivotal role in detecting diseases and monitoring conditions. Even a slight deviation in their performance can result in incorrect diagnoses, leading to inappropriate treatments. Regular calibration ensures these devices maintain optimal accuracy, empowering healthcare providers to make informed decisions.

- Ensuring patient safety: Incorrectly calibrated devices pose severe risks to patients, especially in life-critical scenarios. For instance, inaccurate readings from ventilators or defibrillators can have dire consequences. Calibration acts as a safety net, ensuring these devices deliver accurate results and safeguard patient lives.

- Promoting compliance with regulatory standards: Healthcare facilities must meet stringent regulations set by accrediting bodies like ISO and NABH. Routine calibration not only ensures compliance but also instills trust among patients, insurance providers, and stakeholders. Non-compliance could result in penalties, suspension of operations, and damage to reputation.

- Minimizing financial liabilities: Devices that malfunction due to poor calibration can lead to expensive repairs, frequent replacements, and legal consequences arising from medical errors. Regular calibration mitigates these risks, reducing costs associated with unexpected downtime and liabilities.

- Boosting healthcare efficiency: Efficient healthcare delivery hinges on seamless operations. Calibrated devices ensure healthcare providers can deliver prompt, accurate diagnoses and treatments, optimizing patient outcomes and hospital workflows.

Key equipment requiring calibration in hospitals

1. Imaging and diagnostic devices

- X-ray and MRI machines: Essential for accurate imaging, ensuring proper calibration prevents misdiagnosis caused by blurred or incorrect scans.

- CT scanners: Calibration guarantees precise cross-sectional imaging, critical for detecting internal injuries and conditions.

- Ultrasound devices: Proper alignment ensures accurate real-time imaging for monitoring fetal health and internal organs.

- Mammography equipment: Calibrated devices help detect abnormalities in breast tissue with precision and clarity.

2. Therapeutic equipment

- Infusion pumps for drug administration: Calibration ensures accurate drug dosages, avoiding under or overdosing risks.

- Surgical lasers: Properly calibrated lasers provide precision in surgeries, minimizing tissue damage and enhancing patient recovery.

- Radiation therapy equipment: Accurate calibration guarantees that patients receive the correct dose of radiation during cancer treatments.

3. Patient monitoring systems

- Blood pressure monitors: Calibrated monitors deliver reliable readings, vital for managing critical care patients.

- ECG and pulse oximeters: Ensure accurate measurement of heart rhythms and blood oxygen levels for timely interventions.

- Thermometers and capnographs: Calibration provides precise body temperature and respiratory CO₂ levels, essential for monitoring critical patients.

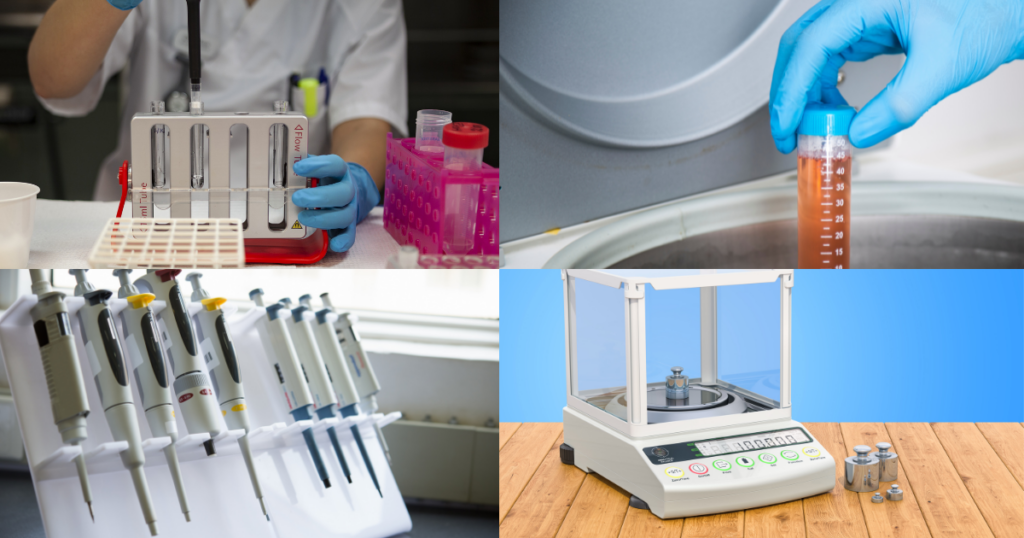

4. Laboratory instruments

- Hematology analyzers: Proper calibration ensures accuracy in blood tests, crucial for diagnosing a range of conditions.

- Centrifuges and pipettes: Accurate functioning ensures correct sample preparation and measurement for laboratory tests.

- Analytical balances: Calibrated balances guarantee precise weight measurements for chemical and medication preparation.

5. Other medical devices

- Defibrillators: Calibration ensures the device delivers accurate electrical shocks during life-saving interventions.

- Autoclaves: Proper calibration maintains the required pressure and temperature for effective sterilization.

- Ventilators and anesthetic machines: Ensures accurate airflow and gas mixtures to support patient care during surgeries and respiratory issues.

The calibration process: step-by-step guide

- Pre-calibration assessment: Experts inspect the device for wear and tear, verifying all components to ensure no physical damage compromises calibration.

- Use of reference standards: Devices are calibrated using highly accurate reference instruments traceable to global standards such as ISO or NIST. This step ensures consistency and global compatibility.

- Performance testing and adjustment: The equipment’s readings are compared against reference values. Discrepancies are corrected to align performance with specified tolerances.

- Certification and documentation: Once calibration is complete, a certificate detailing the procedure, equipment condition, and compliance is issued. Comprehensive documentation is essential for audits and future reference.

- Final review: The equipment undergoes a final review to ensure it operates smoothly post-calibration. Records are securely maintained to track calibration history.

Challenges in calibration and how prism calibration addresses them

- Diverse device specifications: Medical devices have varied requirements, making calibration complex. Prism Calibration employs cutting-edge tools and certified professionals adept at handling a wide range of medical equipment.

- Strict timelines: Hospitals operate round the clock, with minimal room for equipment downtime. Our rapid calibration services minimize disruptions, ensuring devices are operational without compromising quality.

- Regulatory compliance: Hospitals must meet evolving regulations to maintain certifications. Prism Calibration stays updated with international standards, helping facilities avoid non-compliance risks.

- Tailored solutions: Each hospital has unique needs. Prism Calibration offers customizable calibration packages to meet specific requirements, be it for a small clinic or a multi-specialty hospital.

The benefits of partnering with prism calibration

- Industry expertise: Prism Calibration has years of experience in providing calibration services for critical healthcare equipment, ensuring exceptional accuracy.

- Comprehensive support: From initial inspection to certification, we manage the entire calibration lifecycle with precision.

- Regulatory confidence: Our services guarantee compliance with ISO, NABL, and other global standards.

- Technology-driven solutions: Prism uses advanced tools and software to deliver precise calibration, minimizing human error.

- Cost efficiency: Our services extend equipment lifespan, reducing maintenance and replacement costs.

- 24/7 emergency assistance: Prism Calibration understands the urgency of healthcare operations and provides round-the-clock support.

Regular calibration: A long-term investment

Healthcare equipment calibration is not a one-time task but an ongoing process critical to operational excellence. Hospitals investing in calibration reap long-term benefits, including improved patient care, minimized risks, and streamlined workflows. Calibration enhances trust among patients and stakeholders, solidifying the hospital’s reputation for delivering top-notch healthcare.

Conclusion

Hospital equipments calibration is the backbone of patient safety, diagnostic accuracy, and healthcare efficiency. Neglecting it can lead to severe consequences, from medical errors to non-compliance penalties. With Prism Calibration, hospitals gain a reliable partner dedicated to maintaining equipment accuracy and safeguarding patient health.

Ensure the safety and reliability of your healthcare services today. Visit Prism Calibration for unparalleled calibration expertise.

Author Bio

Mr. Parthiv Kinariwala is a leading expert in calibration and testing services, with over 20 years of experience in the industry. As the founder of Prism Calibration, established in 2004, Mr. Kinariwala has been at the forefront of delivering precise and reliable calibration, testing, and validation solutions across various industries. His expertise in providing services that meet international calibration standards has earned the trust of major clients, including Reliance Industries, Zydus Cadila, Indian Oil, ONGC, Adani, and Tata.

With a deep understanding of instrumentation, measurement accuracy, and industrial testing, Mr. Kinariwala ensures that each client receives exceptional service tailored to their specific needs. His unwavering commitment to quality and precision has established Prism Calibration as a trusted partner for some of the largest and most respected organizations in the industry.