Rotameter calibration is a critical process for ensuring the accuracy and reliability of flow measurement devices used across industries such as pharmaceuticals, oil and gas, chemical processing, and water treatment. At Prism Calibration, we specialize in providing precision rotameter calibration services that meet the highest international standards, including ISO Certification and NIST Traceability. Whether you need calibration for liquid or gas flow meters, our advanced calibration methods ensure optimal performance, compliance, and operational efficiency.

Rotameters, also known as variable area flow meters, are widely used to measure the flow rate of liquids and gases. However, over time, factors like wear and tear, environmental conditions, and improper handling can lead to inaccuracies. Regular calibration ensures that your rotameter continues to provide precise and reliable measurements, which are essential for maintaining process efficiency, safety, and regulatory compliance.

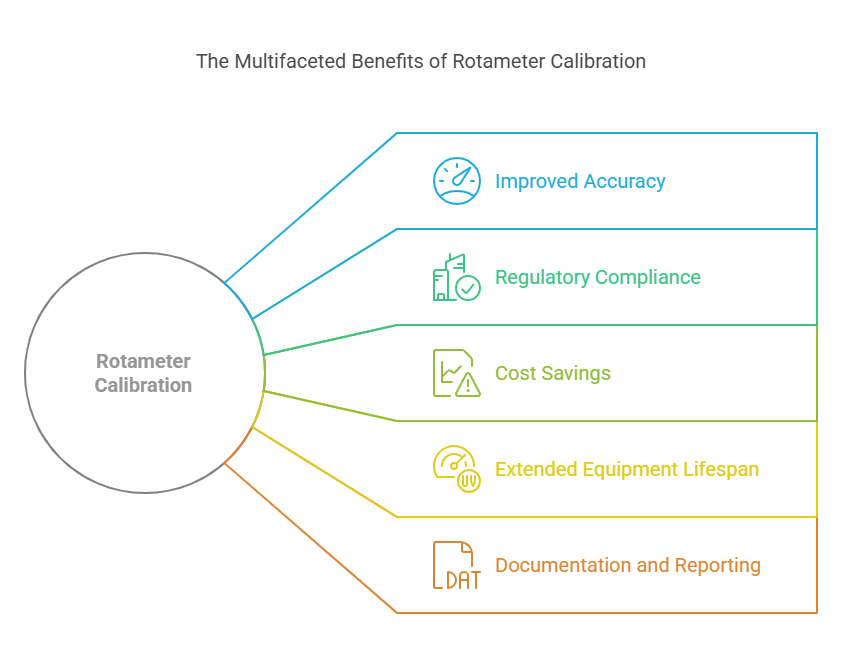

Rotameters are indispensable instruments for measuring the flow rate of liquids and gases in industrial processes. Over time, factors like wear and tear, environmental conditions, and improper handling can lead to inaccuracies. Regular calibration ensures:

Improved accuracy: Precise flow measurements for better process control.

Regulatory compliance: Meeting industry standards such as ISO and NIST Traceability.

Cost savings: Preventing costly errors and downtime caused by inaccurate measurements.

Extended equipment lifespan: Proper calibration reduces wear and tear, extending the life of your flow meters.

Documentation and reporting: Detailed calibration reports for audits and quality assurance.

In industries where even a small measurement error can lead to significant consequences, such as pharmaceuticals or oil and gas, regular rotameter calibration is not just a best practice—it’s a necessity. Calibration ensures that your flow meters are operating within their specified accuracy range, which is critical for maintaining product quality, safety, and regulatory compliance.

Connecting a rotameter for calibration requires precision and expertise to ensure accurate results. Here’s a step-by-step guide:

Preparation

Ensure the rotameter is clean and free from debris.

Verify that the rotameter is properly installed and aligned.

Connection setup

Connect the rotameter to the calibration equipment using appropriate fittings and adapters.

Ensure all connections are secure to prevent leaks.

Flow testing setup

Set up the flow testing equipment to simulate various flow rates.

Ensure the reference standard is properly calibrated and ready for use.

Initial testing

Conduct an initial flow test to identify any discrepancies.

Record the initial readings for comparison.

Adjustments

If any inaccuracies are detected, make necessary adjustments to the rotameter.

Re-test to ensure the adjustments have restored accuracy.

Final verification

Conduct a final flow test to verify the rotameter’s accuracy.

Ensure all readings are within the acceptable range.

Properly connecting the rotameter for calibration is crucial for obtaining accurate results. At Prism Calibration, our expert technicians follow a meticulous process to ensure that your rotameter is properly connected and calibrated, providing you with reliable and precise flow measurements.

At Prism Calibration, we follow a meticulous and transparent rotameter calibration process to ensure the highest level of accuracy and reliability. Here’s a step-by-step breakdown of our process:

Initial inspection

We begin by visually inspecting the rotameter for any physical damage or wear.

Check for proper installation and alignment.

Flow testing

Using state-of-the-art flow calibration equipment, we test the rotameter across various flow rates.

Compare the rotameter’s readings against a reference standard to identify discrepancies.

Adjustments

If any inaccuracies are detected, our expert technicians make precise adjustments to restore accuracy.

Ensure the rotameter performs optimally under different flow conditions.

Environmental calibration

We simulate real-world operating conditions by accounting for factors like temperature and humidity control.

This ensures the rotameter performs accurately in its intended environment.

Certification

Once calibrated, the rotameter is issued a calibration certificate with NIST Traceability.

The certificate includes detailed information about the calibration process and results.

Documentation and reporting

We provide comprehensive calibration reports, including test data, adjustments made, and compliance with ISO standards.

These reports are essential for audits and quality assurance.

Our calibration process is designed to ensure that your rotameter is operating at peak performance, providing you with accurate and reliable flow measurements.

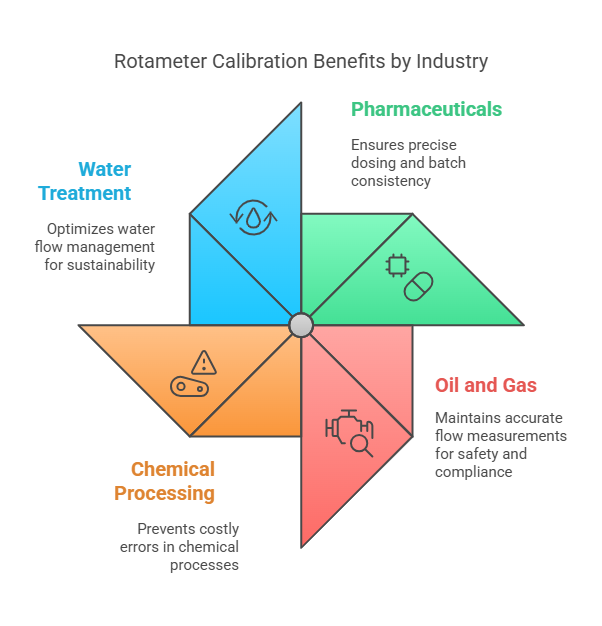

Our industrial flow meter calibration services are tailored to meet the unique needs of various industries. Here’s how we add value to your business:

Pharmaceuticals: Ensure precise dosing and batch consistency for drug manufacturing.

Oil and Gas: Maintain accurate flow measurements for safety, efficiency, and regulatory compliance.

Chemical processing: Prevent costly errors in chemical mixing and transfer processes.

Water treatment: Optimize water flow management for sustainability and resource conservation.

In each of these industries, accurate flow measurement is critical for maintaining product quality, safety, and regulatory compliance. Regular rotameter calibration ensures that your flow meters are operating within their specified accuracy range, which is essential for achieving these goals.

At Prism Calibration, we adhere to the highest standards of ISO Certification and NIST Traceability to ensure your equipment meets global regulatory requirements. Here’s what this means for you:

ISO certification: Our calibration processes comply with international standards, ensuring accuracy and reliability.

NIST traceability: Our calibration certificates are traceable to the National Institute of Standards and Technology, providing confidence in the accuracy of your measurements.

Documentation and reporting: We provide detailed calibration reports, including test data, adjustments made, and compliance with ISO standards.

Compliance with these standards is essential for maintaining regulatory compliance and ensuring the accuracy and reliability of your flow measurements.

When it comes to rotameter calibration services, Prism Calibration stands out as a trusted partner. Here’s why:

Expertise and experience

With years of experience in flow meter calibration, our team has the knowledge and skills to handle even the most complex calibration challenges.

State-of-the-art facilities

Our calibration labs are equipped with advanced technology and equipment to ensure precise and reliable results.

Compliance with international standards

We adhere to ISO Certification and NIST Traceability standards, ensuring your equipment meets global regulatory requirements.

Comprehensive service offerings

From liquid and gas flow meter calibration to rotameter accuracy testing, we offer a wide range of services to meet your needs.

Quick turnaround time

We understand the importance of minimizing downtime, so we provide fast and efficient calibration services.

Transparent and detailed reporting

Our calibration reports are thorough, easy to understand, and include all necessary documentation for audits and compliance.

Customer-centric approach

We prioritize your needs and work closely with you to deliver customized solutions that meet your specific requirements.

Ensure the accuracy and reliability of your flow meters with Prism Calibration’s expert rotameter calibration services. Contact us today to schedule your calibration or learn more about our flow meter certification services. Let us help you achieve precision, compliance, and operational excellence.

Rotameter calibration is the process of adjusting and testing flow meters to ensure they provide accurate flow measurements.

The frequency depends on usage and industry standards, but we recommend annual calibration for most applications.

Yes, all calibrated rotameters come with a NIST Traceable calibration certificate.

Absolutely! We specialize in liquid and gas flow meter calibration.

We adhere to ISO Certification and NIST Traceability standards.

The turnaround time depends on the complexity of the calibration, but we strive to complete most calibrations within 2-3 business days.