In the world of manufacturing, engineering, and scientific research, precision is not just a goal; it’s a necessity. Instruments and equipment that provide inaccurate measurements can lead to product defects, safety hazards, and non-compliance with industry standards. This is where calibration services play a critical role. In this blog post, we will explore the importance of calibration services, the benefits they offer, and how Prism Calibration Centre can help your business maintain the highest standards of accuracy and reliability.

The Role of Calibration in Quality Assurance:

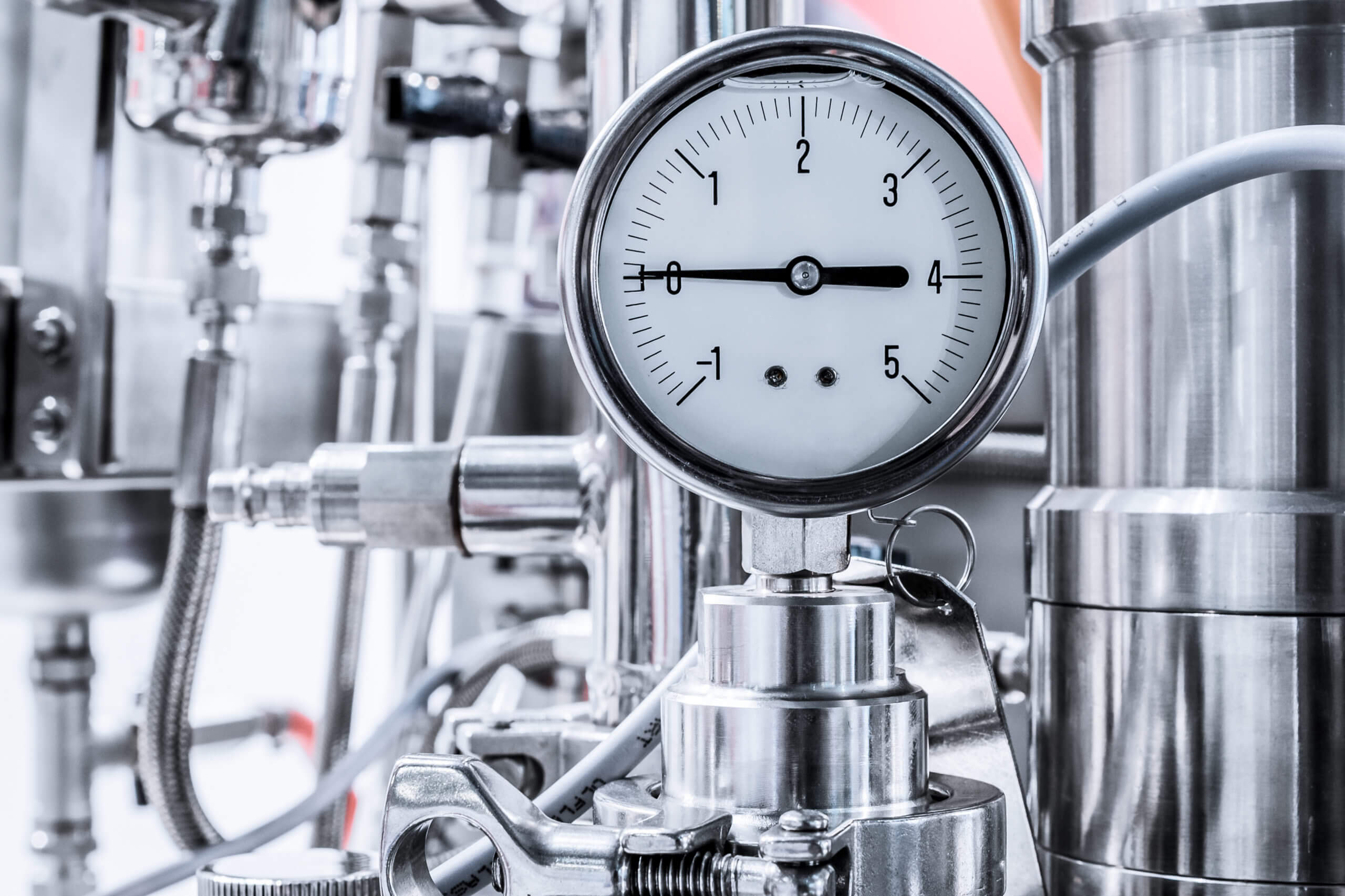

Calibration is the scientific process of determining the accuracy of an equipment’s measurements against a known standard. It ensures that instruments such as thermometers, pressure gauges, and digital multimeters are providing precise readings, which is essential for quality assurance in any industry. Regular calibration protects against equipment drift over time and helps to identify any potential issues before they lead to significant errors.

Why Choose Prism Calibration Centre?

Prism Calibration Centre is a leading provider of calibration services, offering a comprehensive range of solutions to meet the diverse needs of businesses across various sectors. With a commitment to excellence and a team of highly skilled technicians, Prism Calibration Centre ensures that your equipment is calibrated to the highest standards.

Services Offered by Prism Calibration Centre:

- Equipment Calibration: Prism Calibration Centre specializes in calibrating a wide array of instruments, from simple hand tools to complex analytical equipment, ensuring they meet the required accuracy specifications.

- Certification: All calibrations come with a certificate that provides documented evidence of traceability to national or international standards, which is vital for ISO certification and regulatory compliance.

- Repair and Maintenance: In cases where equipment fails calibration, Prism Calibration Centre offers repair services to get your instruments back to optimal performance.

- On-site Calibration: For machinery and equipment that cannot be moved, Prism Calibration Centre provides on-site calibration services to ensure minimal disruption to your operations.

- Customized Calibration Programs: Tailored calibration schedules and programs are designed to meet the unique needs of your business, ensuring all equipment is calibrated in a timely and efficient manner.

- Consultation: Expert advice on measurement uncertainties, calibration methodologies, and compliance with standards is available to help your business stay ahead.

- Training: Prism Calibration Centre offers training programs to educate your staff on best practices for equipment handling, use, and maintenance, reducing the risk of calibration drift.

Why Calibration is Important?

The Benefits of Regular Calibration:

- Enhanced Product Quality: Accurate measurements lead to better quality products and fewer defects.

- Increased Safety: In industries where safety is paramount, such as aerospace and healthcare, calibration ensures that equipment functions correctly, minimizing risks.

- Cost Savings: Regular calibration can prevent costly equipment failures and the expenses associated with producing and recalling defective products.

- Regulatory Compliance: Calibration is often a requirement for compliance with industry regulations, avoiding potential fines and legal issues.

- Competitive Advantage: Demonstrating a commitment to precision and quality can enhance your brand’s reputation and competitiveness in the market.

In an era where precision engineering and exact measurements are the cornerstones of success, calibration services are indispensable. Prism Calibration Centre is your partner in ensuring that your equipment meets the highest standards of accuracy and reliability. By choosing Prism Calibration Centre, you are not just calibrating your instruments; you are investing in the quality, safety, and future of your business. Contact Prism Calibration Centre today to learn more about how we can support your calibration needs and help you maintain the precision that drives your industry forward.

FAQs (Frequently Asked Questions)

What is calibration and why is it important?

Calibration is the process of verifying the accuracy of measurement instruments by comparing them with a known standard. It ensures that instruments provide precise readings, which is crucial for maintaining quality, safety, and compliance in various industries.

How often should equipment be calibrated?

The frequency of calibration depends on several factors, including the type of equipment, its usage, and industry regulations. Typically, manufacturers provide guidelines, but it is also advisable to consult with calibration experts like those at Prism Calibration Centre for tailored advice.

What types of equipment can be calibrated at Prism Calibration Centre?

Prism Calibration Centre can calibrate a wide range of instruments, including but not limited to thermometers, pressure gauges, digital multimeters, analytical equipment, and various hand tools.

What certifications do you provide after calibration?

After calibration, Prism Calibration Centre provides a certificate that documents the traceability of measurements to national or international standards. This certification is essential for maintaining ISO compliance and meeting regulatory requirements.

Can you perform on-site calibration services?

Yes, Prism Calibration Centre offers on-site calibration services for equipment and machinery that cannot be easily transported. This service ensures minimal disruption to your operations.

Author Bio

Mr. Parthiv Kinariwala is a leading expert in calibration and testing services, with over 20 years of experience in the industry. As the founder of Prism Calibration, established in 2004, Mr. Kinariwala has been at the forefront of delivering precise and reliable calibration, testing, and validation solutions across various industries. His expertise in providing services that meet international calibration standards has earned the trust of major clients, including Reliance Industries, Zydus Cadila, Indian Oil, ONGC, Adani, and Tata.

With a deep understanding of instrumentation, measurement accuracy, and industrial testing, Mr. Kinariwala ensures that each client receives exceptional service tailored to their specific needs. His unwavering commitment to quality and precision has established Prism Calibration as a trusted partner for some of the largest and most respected organizations in the industry.