Prism Calibration offers power calibration services for all types of equipment. Our highly trained technicians use state-of-the-art equipment to ensure accurate measurements and reliable results.

Power instruments calibration services involve adjusting and verifying the accuracy of instruments used to measure electrical parameters, such as voltage, current, resistance, and power. These services ensure that power measurement devices operate within the required tolerance limits, maintaining their precision and reliability. By regularly calibrating power instruments, industries can avoid costly errors, improve operational efficiency, and ensure compliance with industry standards and regulations.

Regular calibration of power instruments is crucial for maintaining their accuracy and performance. Over time, instruments may drift or degrade due to environmental factors, usage, or internal component wear. Regular calibration ensures that the instruments deliver precise readings, which are essential for:

Improved Accuracy: Ensures that all measurements are accurate, preventing costly mistakes or system inefficiencies.

Compliance: Helps businesses meet industry regulations and standards.

Reduced Downtime: Prevents unexpected failures by identifying issues before they become major problems.

Cost Savings: Accurate instruments help optimize energy usage and reduce waste, leading to significant cost savings.

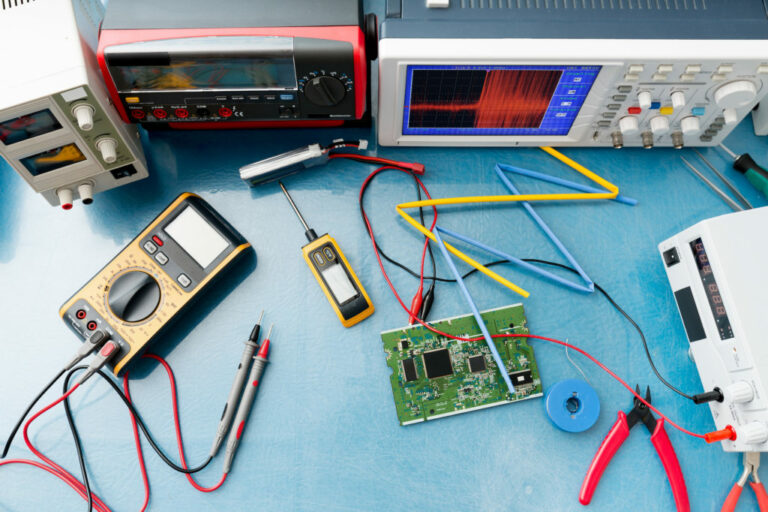

To calibrate a power instrument properly, you’ll need the following:

The Power Instrument: The device you wish to calibrate, such as a voltmeter, ammeter, or power meter.

Calibration Standards: A standard reference device, such as a precision calibrator or known standard with traceable accuracy.

Adapters and Connectors: Depending on the type of power instrument, you may need specific connectors or adapters to establish a secure connection.

Safety Gear: Personal protective equipment (PPE) like gloves, goggles, and other necessary safety gear.

Stable Calibration Environment: A controlled environment free from temperature fluctuations, humidity, or vibrations to ensure reliable results.

Power calibration services offer several benefits to industries and businesses that rely on accurate power measurement. Here are some key benefits of power calibration services:

Accuracy and Reliability: Power calibration ensures that your power measurement instruments provide accurate and reliable readings. Calibration compares the measurements of your instruments against traceable standards, identifying any deviations or errors and allowing adjustments to be made. Accurate power measurements enable better decision-making, improved quality control, and increased confidence in your power data.

Compliance with Standards: Many industries have regulatory standards and requirements for power measurement accuracy. Power calibration services ensure that your instruments meet these standards, helping you maintain compliance with industry regulations. Calibration certificates provide documented evidence of compliance, which is often necessary for audits, certifications, and regulatory inspections.

Optimized Performance: Regular calibration helps identify any drift, non-linearity, or inaccuracies in power measurement instruments. By detecting and rectifying these issues, calibration helps optimize the performance of your instruments, ensuring they deliver accurate measurements. This leads to improved operational efficiency, reduced errors, and enhanced productivity.

Cost Savings: Calibration helps prevent costly errors and inefficiencies that may arise from inaccurate power measurements. Accurate measurements can lead to more efficient energy consumption, reduced waste, and better resource allocation. By maintaining accurate power measurements, you can avoid unnecessary expenses associated with rework, product failures, or non-compliance penalties.

Increased Equipment Lifespan: Power calibration often includes preventive maintenance checks and adjustments. Regular calibration and maintenance can extend the lifespan of your power measurement instruments by identifying and addressing potential issues early on. This reduces the risk of instrument failures and the need for premature replacements, ultimately saving you costs in the long run.

Quality Assurance: Accurate power measurements are crucial for quality control and product testing processes. Calibration ensures that your instruments provide reliable data for quality assurance, helping you maintain consistent product quality and reliability. It also enhances customer satisfaction by ensuring that your products meet or exceed performance specifications.

Traceability and Documentation: Power calibration services provide traceability by comparing measurements against recognized standards. Calibration certificates serve as documented evidence of calibration and compliance, offering traceability to national or international standards. These certificates can be easily accessed and stored for record-keeping, audits, and regulatory purposes.

Proper connection of power instruments during calibration is vital for ensuring accurate results. Follow these steps:

Secure the Instrument: Place the power instrument in a stable position, free from vibration or movement.

Connect the Instrument to the Reference Device: Use appropriate cables and adapters to connect the instrument to the standard reference device (calibrator). Ensure all connections are tight and secure.

Check for Proper Setup: Double-check that all settings, such as measurement ranges, are correctly configured to match the instrument’s operating parameters.

Verify Power Supply: Ensure that the instrument is properly powered, and any electrical connections are safely configured, especially when working with high voltage or current.

Gather all the necessary tools, including the power instrument, reference standard, adapters, and safety equipment. Ensure the calibration environment is stable and safe.

Secure the instrument in a stable position and connect it to the calibrator using proper adapters. Set the calibrator to the same measurement range as the power instrument.

After adjustments, verify the instrument’s readings at multiple points within its range to ensure accuracy. Confirm the instrument operates within acceptable tolerance limits.

Record the calibration results, including any adjustments made and final readings, for future reference and compliance.

Regular Calibration: Schedule regular calibration to ensure instruments continue to perform at peak accuracy.

Use Certified Calibration Standards: Ensure your reference devices are certified and traceable to national or international standards.

Document All Calibration Results: Keep detailed records of calibration data for compliance and future reference.

Perform Calibration in Controlled Environments: Minimize environmental interference by calibrating in temperature and humidity-controlled settings.

Test Across Full Range: Calibrate the instrument at multiple points within its full range to ensure accuracy across all measurement levels.

Expert Calibration Services: Use professional calibration services to ensure that instruments are properly calibrated and meet industry standards.

When selecting a power instruments calibrator, it’s important to consider factors like the calibrator’s accuracy, range, and traceability to national or international standards. A high-quality calibrator should provide:

Traceable Accuracy: It must be calibrated against recognized standards to ensure the highest precision.

Wide Measurement Range: The calibrator should cover the full range of measurements needed for the instruments you use.

Ease of Use: Choose a calibrator that is user-friendly and comes with clear instructions for setup and operation.

Durability: A reliable calibrator should be built to last and withstand frequent use.

Regular calibration ensures that power instruments maintain accuracy over time, preventing errors and ensuring compliance with standards.

Common power instruments that require calibration include voltmeters, ammeters, power meters, and frequency counters.

Calibration frequency depends on usage, industry standards, and the precision required. Typically, it’s recommended to calibrate instruments annually or biannually.

While some basic calibrations can be done in-house, it’s best to use professional calibration services for high-accuracy instruments or complex setups.

Look for calibration service providers with certified standards, experienced technicians, and a proven track record in the industry.

Calibration adjusts the instrument to ensure accuracy, while verification checks that the instrument is performing within acceptable tolerance limits.

If readings are inconsistent, erratic, or not in line with known standards, it may be time for a recalibration.