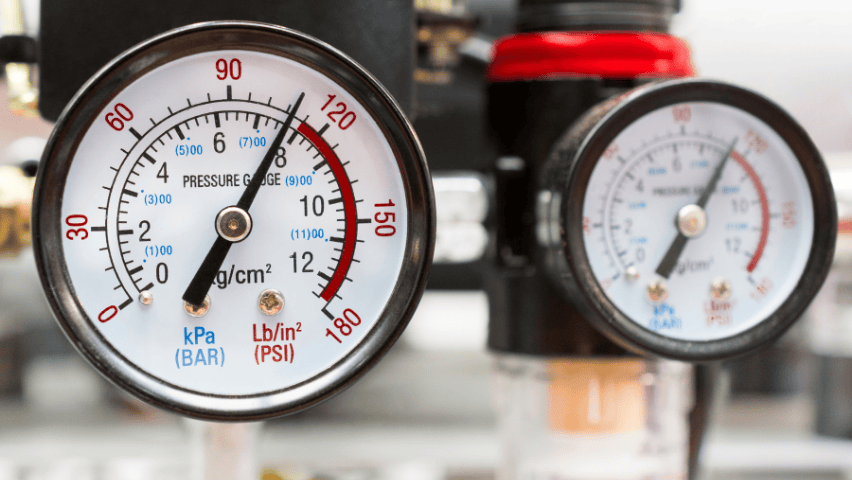

Accurate pressure measurement is vital across industries — from pharmaceutical manufacturing and HVAC to oil, gas, and food processing. Over time, pressure gauges can drift from their original accuracy due to regular use, environmental exposure, and mechanical wear. That’s why pressure gauge calibration is essential to ensure reliable performance, safety, and compliance.

At Prism Calibration, we offer reliable, traceable, and cost-effective pressure gauge calibration services for a wide range of instruments, including analog and digital gauges, vacuum gauges, pressure sensors, and transducers. All our services are carried out in a NABL-traceable environment.

Pressure gauge calibration is the process of verifying and adjusting the readings of a pressure gauge against a known reference standard. This ensures the readings shown by the instrument are accurate and within specified tolerance levels.

Regular calibration helps

Prism Calibration ensures all procedures strictly follow NABL-traceable standards for reliable results every time.

Even a small deviation in pressure reading can affect critical processes. For instance, in pharmaceuticals, inaccurate pressure can lead to batch failures. That’s why periodic calibration of pressure gauges and sensors is important.

Pressure gauges monitor essential parameters in boilers, pipelines, and reactors. Misreading can lead to dangerous failures. Calibration reduces the risk of accidents and ensures equipment runs within safe pressure limits.

Industries are required to follow standards like ISO 9001, GMP, or FDA. Regular pressure gauge calibration services are a mandatory part of these audits. NABL accreditation plays a key role in meeting these regulatory needs.

Our calibration is done using high-accuracy deadweight testers, pressure comparators, and digital reference standards. The general steps include:

– Visual Inspection – Check for physical damage or wear

-Connection to Master Equipment – Reference device with higher accuracy

– Apply Pressure in Steps – Record readings at increasing and decreasing pressure points

– Compare Readings – Between the test device and the standard

-Adjust or Report – If the gauge is out of tolerance

At Prism Calibration, all steps are documented and aligned with NABL traceability protocols.

All pressure calibrations are done using NABL-traceable master instruments. Our pressure gauge calibration machines are regularly maintained and certified to ensure they meet national and international standards.

We also provide:

At Prism Calibration, we provide calibration services across a wide array of industries, ensuring precision, compliance, and operational efficiency. Our services are tailored to meet the specific needs of the following key sectors:

After calibration, Prism Calibration provides detailed certification and documentation, ensuring traceability and compliance.

– ISO 17025 Calibration Certificate: Official documentation verifying accuracy.

– Test Reports: Comprehensive analysis of pre- and post-calibration results.

– NIST Traceability Statement: Proof of adherence to NIST measurement standards.

– Calibration Stickers & Labels: Marking next calibration due date and service details.

– Regulatory Compliance Documentation: Required for audits and industry certifications.

This documentation serves as proof of compliance and helps organizations maintain quality assurance records.

At Prism Calibration, we offer flexible calibration options to meet your specific needs:

– Onsite calibration: Our onsite calibration service brings our expert technicians directly to your facility, ensuring that large, stationary, or difficult-to-transport equipment is calibrated with minimal disruption to your operations. We bring all necessary tools and reference standards, so you can rely on accurate results at your location.

– In-Lab calibration: For portable instruments or systems that can be easily transported, our in-lab calibration provides an ideal solution. You can send your equipment to our state-of-the-art facility, where we will perform the calibration with precise instruments and controlled conditions. Our lab ensures high-quality, traceable results for a wide range of devices.

Why choose both options?

– Convenience: We understand that every calibration need is unique, so we offer both options to ensure you have a service tailored to your operational needs.

– Accuracy: Whether onsite or in-lab, our expert technicians ensure precise and reliable calibration, so your equipment functions optimally.

– Reduced downtime: Both options are designed to minimize downtime and keep your business running smoothly, with fast turnaround times for all services.

It depends on the application, usage frequency, and industry regulations. Generally, calibration is recommended once a year.

Yes, we offer onsite calibration services for industries and plants where equipment cannot be removed.

Both involve verifying pressure readings, but transducers convert pressure into an electrical signal, so electrical parameters are also checked.

Yes, all our calibration equipment is traceable to NABL-accredited standards.

Absolutely. We have specialized setups for vacuum gauge calibration, including both analog and digital models.

Yes. We support batch calibration with documentation for each device.