Ensure precise viscosity measurements and regulatory compliance with ISO 17025 certified viscometer calibration services from Prism Calibration. We specialize in calibrating a wide range of viscometers—including Brookfield, Anton Paar, capillary, and rotational viscometers—using NABL accredited procedures and NIST-traceable standards.

Proper calibration of your viscometer is essential to maintain:

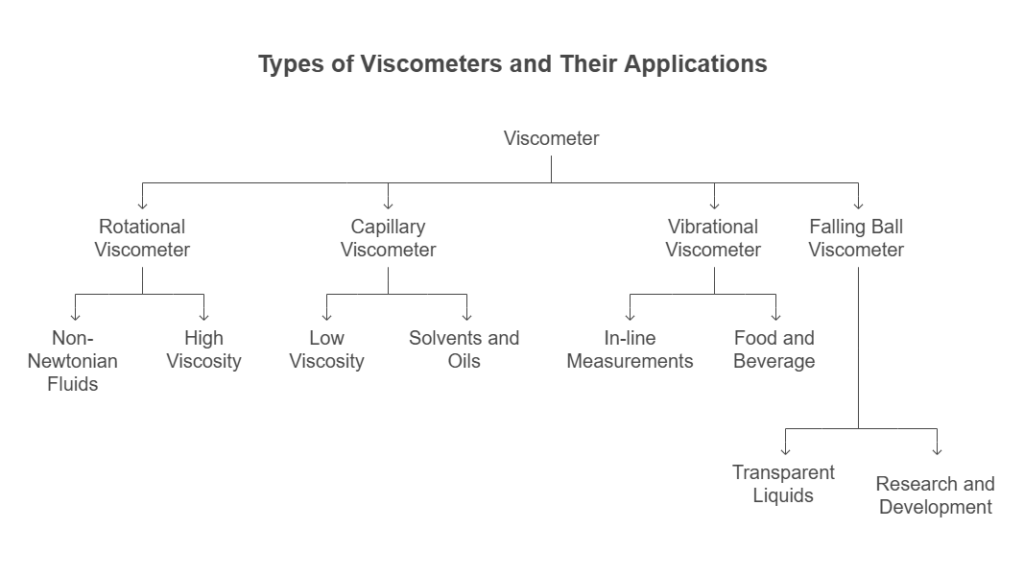

A viscometer is an instrument used to measure the viscosity of liquids, which is the resistance of a fluid to flow. Accurate viscosity measurements are critical in industries like pharmaceuticals, chemicals, and food processing. Here are the main types of viscometers:

– Measure viscosity by rotating a spindle in the liquid.

– Ideal for non-Newtonian fluids and high-viscosity liquids.

– Commonly used in industries like pharmaceuticals and food processing.

– Measure the time it takes for a liquid to flow through a capillary tube.

– Suitable for low-viscosity liquids like solvents and oils.

– Widely used in the chemical and petroleum industries.

– Measure viscosity by analyzing the damping of vibrations in a probe immersed in the liquid.

– Ideal for in-line viscosity measurements in industrial processes.

– Commonly used in the food and beverage industry.

– Measure the time it takes for a ball to fall through a liquid.

– Suitable for transparent liquids with low to medium viscosity.

– Often used in research and development laboratories.

Viscometer calibration is essential across various industries to ensure accurate viscosity measurements and compliance with quality standards. Here’s how viscometer calibration is applied in specific sectors:

– Rotational Viscometer Calibration: Ensures accurate viscosity measurements of drilling fluids and lubricants.

– Benefits: Improves drilling efficiency, reduces equipment wear, and ensures compliance with ASTM standards.

– Applications: Drilling muds, lubricating oils, and hydraulic fluids.

– Capillary Viscometer Calibration: Ensures accurate viscosity measurements of solvents, polymers, and resins.

– Benefits: Enhances product quality, reduces waste, and ensures compliance with ISO standards.

– Applications: Paints, coatings, adhesives, and chemical solutions.

– Rotational Viscometer Calibration: Ensures accurate viscosity measurements of syrups, creams, and gels.

– Benefits: Ensures product consistency, meets FDA regulations, and complies with GMP standards.

– Applications: Liquid medications, topical creams, and injectable solutions.

– Vibrational Viscometer Calibration: Ensures accurate viscosity measurements of sauces, beverages, and dairy products.

– Benefits: Improves product quality, ensures consistency, and complies with HACCP standards.

– Applications: Sauces, dressings, beverages, and dairy products.

Calibration ensures that your viscometer provides accurate and reliable viscosity measurements, which are critical for:

– Product Quality: Ensures consistency and quality of products in industries like pharmaceuticals and food.

– Regulatory Compliance: Meets requirements for certifications like ISO 17025, ASTM, and FDA.

– Operational Efficiency: Prevents costly errors and downtime by ensuring accurate measurements.

– Safety: Ensures that processes involving viscous liquids operate within safe parameters.

– Traceability: Provides documented proof of compliance through calibration certificates.

At Prism Calibration, we follow a meticulous step-by-step calibration process to ensure your viscometers meet the highest standards. Here’s how we do it:

– Evaluate the viscometer’s performance and identify calibration needs.

– Determine the appropriate calibration intervals based on usage and industry requirements.

– Use traceable standards and reference fluids for comparison.

– Ensure the calibration environment is controlled to avoid external factors affecting the results.

– Fine-tune the viscometer to correct any deviations from the standard.

– Use advanced tools and techniques to achieve viscosity measurement accuracy.

– Test the viscometer to ensure it meets metrological standards.

– Perform multiple tests to confirm consistency and reliability.

– Provide detailed calibration certificates that include performance data, adjustments made, and compliance information.

– Ensure the documentation is ready for audits and inspections.

– Recommend calibration intervals and maintenance tips to avoid future errors.

– Offer on-site calibration services for added convenience.

At Prism Calibration, we leverage advanced technologies to enhance the accuracy and efficiency of our calibration services. These include:

– Reduce human error and improve consistency.

– Enhance the speed and accuracy of the calibration process.

– Ensure accurate viscosity measurements by controlling the temperature of the calibration environment.

– Critical for fluids with temperature-dependent viscosity.

– Provides precise and traceable calibration data.

– Ensures documentation and compliance with industry standards.

Regular calibration offers numerous advantages for industries relying on viscometers, including:

– Ensures your viscometers provide reliable and consistent data, reducing the risk of errors.

– Helps you meet industry standards and avoid penalties or legal issues.

– Provides documented proof of compliance through calibration certificates.

– Prevents costly operational errors and equipment failures by identifying issues early.

– Reduces the need for expensive repairs or replacements.

– Minimizes downtime by ensuring your viscometers are always in optimal condition.

– Improves workflow efficiency by reducing the likelihood of errors.

– Regular calibration and preventive maintenance extend the lifespan of your viscometers.

– Reduces the frequency of replacements and repairs.

We adhere to the highest industry standards and certifications, including:

– Ensures the competence of testing and calibration laboratories.

– Guarantees measurement accuracy and traceability.

– Provides documented proof that calibration results are aligned with national standards.

– Ensures transparency and accountability in calibration processes.

– Meets requirements for certifications like ISO 9001, ASTM, and FDA.

– Ensures that your viscometers comply with industry standards.

Viscometer calibration is the process of verifying and adjusting the accuracy of viscometers to ensure they meet metrological standards.

Calibration ensures viscosity measurement accuracy, regulatory compliance, and product quality in industrial operations.

The calibration interval depends on usage and industry requirements, typically ranging from 6 to 12 months.

ISO 17025 certification ensures the competence of testing and calibration laboratories, guaranteeing measurement accuracy and traceability.

Yes, we offer on-site calibration services to minimize equipment downtime and ensure convenience.

We serve industries like oil and gas, chemicals, pharmaceuticals, and food processing.

Yes, we provide detailed calibration certificates for audits and compliance.